The “tiered” rock retaining wall surrounding a pond near a roadway had fallen into disrepair. Since it was long planned to install some sort of low safety barrier which would also serve as a bench at the roadway edge, it was decided to address all needs at the same time.

The “tiered” rock retaining wall surrounding a pond near a roadway had fallen into disrepair. Since it was long planned to install some sort of low safety barrier which would also serve as a bench at the roadway edge, it was decided to address all needs at the same time.

Mark Reed at Olde New England Granite came up with the answer for the appropriate barrier treatment. Not long ago we had reclaimed granite curbing block from The Longfellow Bridge.

It was determined that split down the middle into 16” approximate widths “by feathers & wedges”, the 7’ long granite pieces would serve as an ideal structural and aesthetic barrier.

The attractive split side would face the road and

display the distinctive grain and coloration characteristic of the much sought-after granite from the Deer Isle Quarry off the coast of Maine.

But first … because of discoloration from 100+ years of weathering on the bridge,

But first … because of discoloration from 100+ years of weathering on the bridge,  the granite would be thermaled to restore the original beauty.

the granite would be thermaled to restore the original beauty.

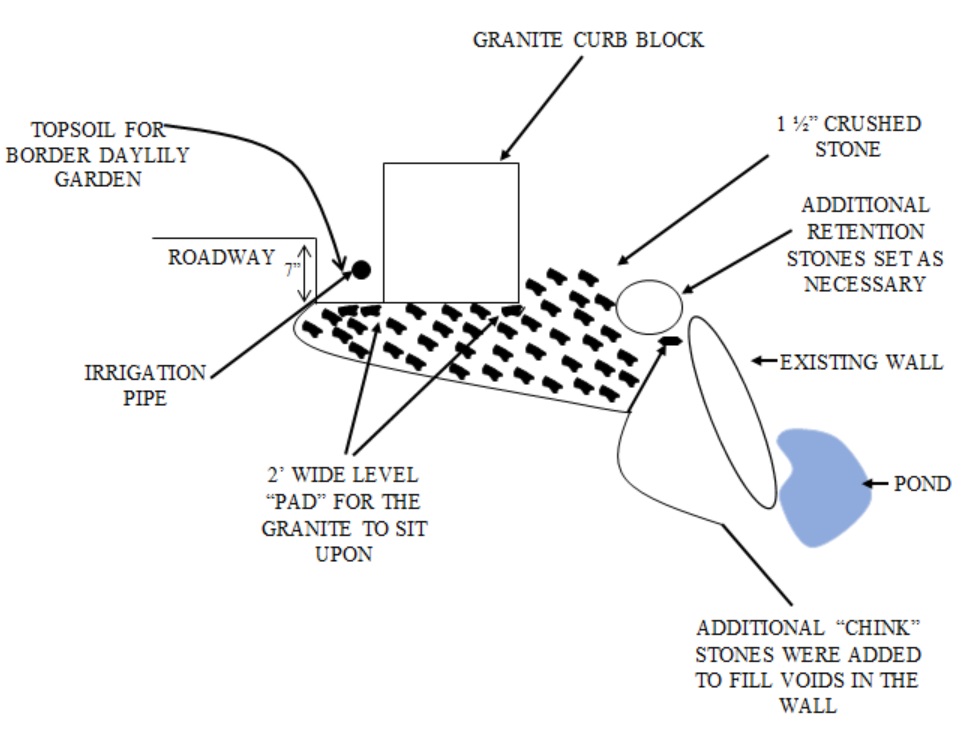

A cross sectional design for the project was sketched up after the desired location of the curb blocks and their footings were marked out with paint, the first order of business was to excavate along the roadway over to the perimeter stones a foot or so deep to acceptable base material. It had been determined that the two culprits for the deteriorating wall were –

• The round river stones which were mistakenly used for the top layer of “fill” around them, acted like “marbles” – aiding and abetting the movement of the upper-level stones towards the pond.

• Years of settling and movement had created gaps allowing for “sink holes” near the stones – that had to be shored up and “chinked” as necessary.

Once the excavation had been completed to the desired depth, “cap” stones were reaffixed to the wall and additional stones shored up gaps. Sink holes were filled with appropriate stones, and any spaces in the wall were “chinked.”

Then a course of 1 ½” CRUSHED stone was placed along the wall to secure and help lock in the top tier of stones. Filter fabric was then laid out in the rest of the trench. More 1 ½” stone was added and leveled out as a shelf 4” below the driveway … as a pad or footing for the granite curb blocks to sit upon. The granite blocks are 16” in depth … it was intended to have a 12” reveal above the road.

A layer of crushed stone secured the perimeter rocks

The filter fabric and pad preparation

The curb blocks are set on the level …

And lined up with a slight “eye-balled” radius conforming to the roadway wall on the opposite side.

“Gaps” of approximately 20” were left between the stones to compensate for “visual unevenness” caused by settling and shifting of the terrain over time. The gaps would be filled with 2 jumbo cobblestones from Olde New England Granite.

Setting JUMBO cobblestones from Olde New England Granite in the gaps Note: the 8” space

between the roadway and the block/cobblestone line will be hand excavated and

prepared for the roadway border garden bed.

The completed block wall will now be ready for the landscape treatment

A light weight “filter fabric” lines the trench and a base layer of topsoil is added. Then the irrigation drip system installed. The water requirements for Daylilies are minimal.

Topsoil is added to grade – and the bed is ready for planting

Hemerocallis “Happy Returns” and wildflower seeds will provide color all season along the roadway.