Installing a Granite “Rumble Strip” – 2018

Often times property owners find a need to connect areas separated by an asphalt driveway – for line voltage, low voltage conduits or irrigation pipes. This poses a problem – what to do? That is… other than cutting the asphalt, excavating, and then patching – NEVER a good look… or paving? Not very cost effective.

Well… the boys at Olde New England Granite have the solution – after the dig – Install a Granite “Rumble Strip” … this will achieve both the objectives – functionality and aesthetics.

In this particular instance we needed to cross an established driveway with 4″ schedule 40 sleeves (which would accommodate irrigation pipes and valve wires.) The only way to access the irrigation main line was to cut across the pavement.

Prior to the asphalt cut, the order is placed with Olde New England Granite – where standard vertical curb pieces are split to length and palletized.

A right angle instrument and chalk line were used to establish the correct location for the cut… and knowing the exact width of the granite curbing, the driveway was marked accordingly (note: for a 2 row “rumble strip” we add an additional 1 ½” to allow for half inch spacing at the center and at each edge.)

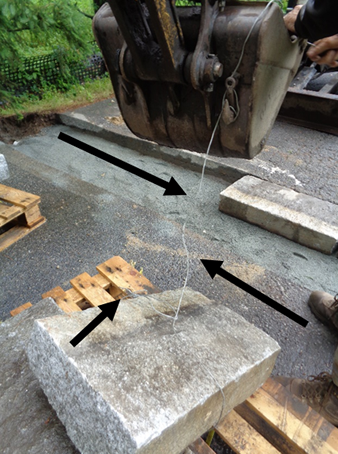

One of the members of our team, John Savage, devised an idea for placement of the granite using a relatively thin wire which is fashioned in a loop – around the granite and lifted from the other end with the excavator. This allows for positioning the granite exactly where it needs to be without disturbing the bed. The wire can usually be pulled out by hand and if it doesn’t come out it can be cut and left. (Note: always start with enough wire – because sometimes the loop breaks from fatigue.)

After the cut has been made the trench excavated and the sleeve(s) installed processed gravel is added to bring to grade and compacted. (Note: a 6″ clearance in depth is needed from the asphalt surface to the bed.) Then stone dust added to adjust to grade necessary for the granite set.

A bar is used to adjust the spacing between the granite.

After the granite is all in place, stone dust is added and swept in the joints.

THE PROJECT IS NOW COMPLETE!